China Power Grid - Wall - climbing Safety Rope - hanging Robot for Electric Towers

In China's power system, the inspection and maintenance of transmission towers are mostly carried out manually. However, there are certain risks in manually climbing towers for maintenance. Usually, the first maintenance worker has to climb the tower with a safety rope and then hang the safety rope to provide safety protection for subsequent climbers. After the maintenance is completed, the last worker also needs to come down with the safety rope. But the first and the last workers have no protection measures during the climbing and returning process, and it is inevitable that events such as personnel falling and other dangerous situations may occur. To address these problems, designing a wall - climbing robot that can autonomously climb electric towers and complete the hanging and disassembly work of safety fall - prevention devices can perfectly solve them.

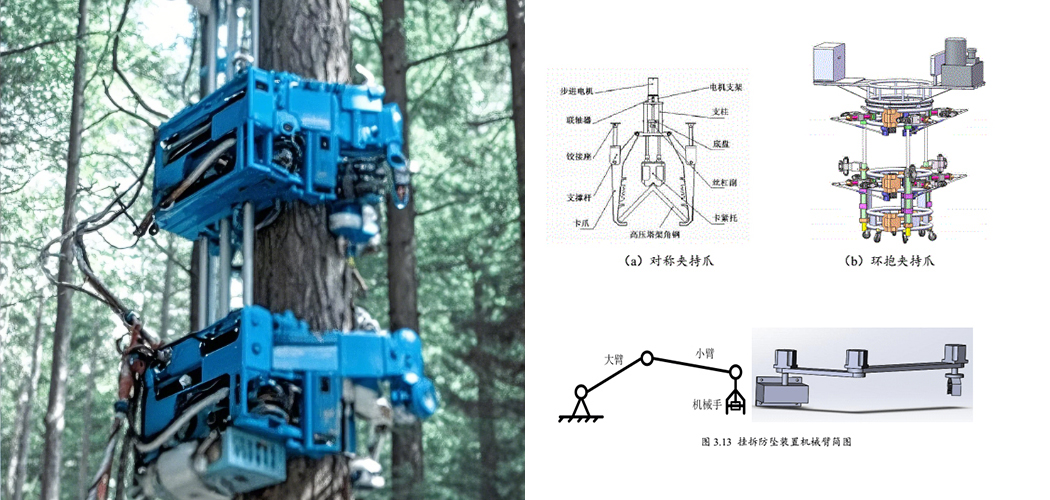

The wall - climbing safety rope - hanging robot for electric towers consists of an upper clamping hand, a lower clamping hand, a traveling mechanism and a robotic arm. The clamping hand is composed of clamping claws, an abduction mechanism and an ejection mechanism. The clamping claws and the abduction mechanisms on the left and right sides are designed according to the diamond centering principle. This symmetrical structural design not only enables the clamping claws to stably contact the angle steel, but also the symmetrically arranged abduction mechanisms have the function of avoiding angle steel obstacles. The function of the ejection mechanism is to ensure that the robot's fuselage is always parallel to the main angle steel during the climbing process, preventing the climbing and obstacle - crossing accuracy of the robot from being affected by the inclination of the fuselage. The extension and retraction of the traveling mechanism can enable the robot to move along the main angle steel, and the linear traveling mechanism can greatly improve the moving efficiency of the robot. When the robot climbs to the set working position, the hanging and disassembly tasks of the fall - prevention device are completed by controlling the movements of each joint of the robotic arm.

The boss in Hangzhou introduced, "Since we introduced the wall - climbing safety rope - hanging robot for electric towers, labor costs have been reduced, sorting efficiency has become higher, and we have also achieved automated integration in query and traceability."