Loading

The Pill-stripping machine is designed to replace manual labor with automated mechanical equipment to solve the tedious manual removal of drug particles from PTP drug plates. Compared with the traditional manual peeling, it has higher work efficiency and reduces labor costs. It has less pollution to drugs in the working process, can be adjusted according to needs, is suitable for a variety of drug packaging specifications, and has no loss to drugs.

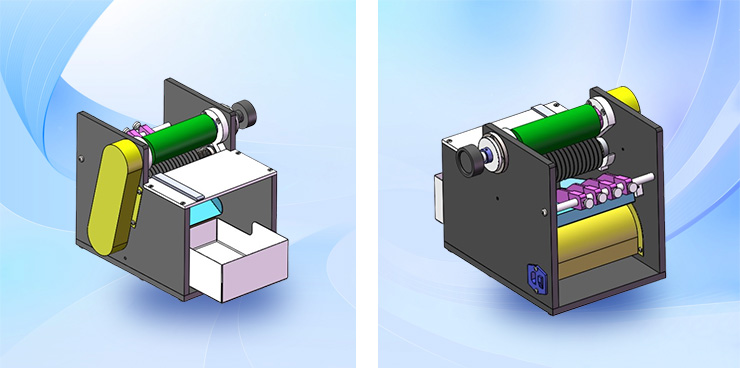

The "Little Cyclone" (JK-BM100) Pill-stripping machine is an automated equipment designed to assist doctors in hospital pharmacies in peeling off PTP drugs packaged in blister aluminum foil and replace repetitive manual labor. The product uses a motor to rotate and drive the squeezing rubber roller, and the PTP drug is squeezed out through the squeezing process to complete the automatic peeling process. The "Little Cyclone" drug stripping machine will be your handy assistant for easy work!

Step 1:place the Pill-stripping machine on a flat desktop.

Step 2 : press the rubber roller and pull out the side shaft.

Step 3: Lift and remove the rubber roller.

Step 4: Place the medicine on the panel and push it to the edge of the baffle along the side slot. Adjust the spacing of the baffles according to the width of the "blister" particles. It is best to keep each baffle 1-2mm away from the edge of the "blister" particle, not too close, as the particles are likely to be damaged in the crushing process. If the spacing of "blister" particles exceeds 4mm, two baffles can be placed between two adjacent "blister" to ensure that the distance between the baffles and "blister" on both sides is within the optimal range of 1-2mm.

Step 5: Place the rubber roller back above the baffle plate, and align the "positioning pin" on both sides of the rubber roller with the pin hole of the bearing seat.

Step 6: Insert the side shaft back into the axle seat while appropriately pressing down the rubber roller, so that the side shaft can smoothly pass through the rubber roller and be inserted into the axle seat at the other end.

Step 7: Turn on the power switch of the equipment, and push the medicines of the same specification into the equipment one by one in the direction of measurement to start the drug stripping operation.

Step 8: Complete the stripping of the drug and turn off the power switch.

01 Usability:Simple operation of disassembly and adjustment, easy to get started.

02 efficiency:Automatic peeling, no missing medicine, no damage to pills, save labor.

03 flexibility:Manual adjustment and decompression with spacing, flexible and convenient, suitable for more specifications of tablet and capsule PTP disassembly.

04 reliability:Stable operation of equipment

which effectively solves the problems of time-consuming, laborious and contaminated drugs existing in manual drug stripping. The equipment is compact, beautiful, lightweight, functional, easy to operate, and low noise, which are quite suitable for our pharmacy environment

he Pill-stripping machine is very small and convenient, does not occupy an area, simple operation, fast hand, it is suitable for use in our pharmacy, can effectively relieve artificial pressure, but also reduce the probability of drug pollution, it is reliable.