Loading

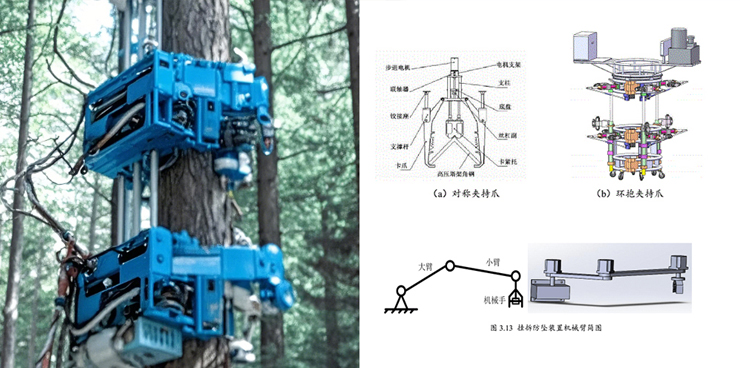

Electric tower wall climbing safety rope hanging robot is a product specially developed for high-altitude power workers, the purpose is to save labor, ensure safety and high efficiency to complete high-altitude work.

Step 1:Power on and start the pylon climbing safety rope to the robot, and check the hardware initialization of the body.

Step 2:Set the climbing height value of the electric tower wall climbing safety rope to connect the robot, grab the action track, and install the operation.

Step 3:Measure the starting position of the high pole.

Step 4:Place the pylon wall climbing safety rope hanging robot on the starting position of the high pole to climb.

Step 5:Click the work button of the Pylon wall climbing safety rope attaching robot .

Step 6: The operator can check the work progress and status of the Pylon wall climbing safety rope attaching robot through real-time feedback images and information

Step 7: If the initial setting operation is wrong, the operator can correct the eighth step through the control panel in time

Step 8:Electric tower wall climbing safety rope hanging robot to complete the operation, upload feedback operation process information.

Step 9:Return to the ground and turn off the power switch.

01. Adsorption ability:The wall climbing robot can fix itself on the wall or surface by adsorption or adhesion to achieve movement and operation in the vertical direction.

02. Positioning and navigation:Wall-climbing robots are usually equipped with positioning and navigation systems that enable them to move accurately on walls and execute specific paths according to task requirements.

03. Power system:wall-climbing robots use batteries or other types of power systems to provide driving force and operational capabilities.

04. Control system:The wall-climbing robot has a comprehensive control system that can control its movement, operation and task execution according to instructions or environmental feedback.

05 Sensors and tools:wall-climbing robots are usually equipped with a variety of sensors, such as cameras, infrared sensors, tactile sensors, etc., can sense the surrounding environment and the conditions of the wall surface, and carry a variety of tools to perform tasks as needed.

High degree of automation:The equipment realizes the fully automated process from climbing, grasping, installation and other operations, greatly reducing manual intervention.

High efficiency and stability:The equipment adopts advanced control system and drive device to ensure efficient and stable operation.

High accuracy:The equipment has a high accuracy in climbing, grasping, installation and other links to ensure the perfect completion of high-altitude work.

Easy maintenance:compact structure, easy maintenance, part of the structure can be quickly disassembled and replaced, easy to clean.

The equipment is currently used in our power grid to reduce a lot of stress for people working at altitude. The equipment is compact, beautiful, lightweight, functional and easy to operate, and these advantages are quite suitable for our working environment